|

MAANSHAN MIDDLE ASIA MACHINE TOOLS MANUFACTURE CO ., LTD

|

Gold Index: 94235

Automatic Pipe bending machine/Metal Sheet press Brake

| Price: | 30170.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

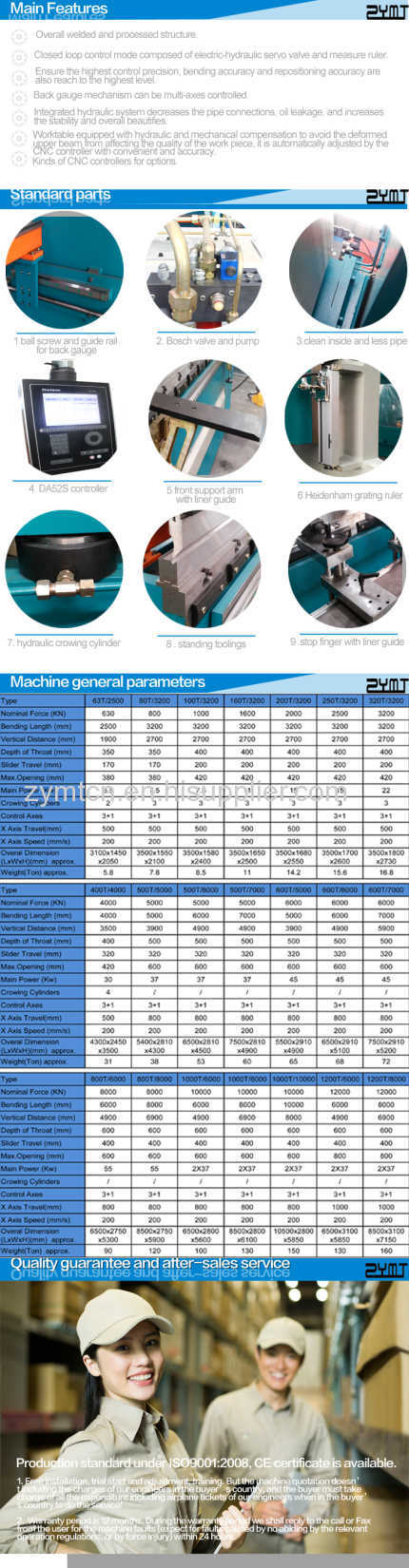

CNC pipe bending machine

high quality metal press brake

Control System: DELEM DA52S

Servo drive and motor: China ESTUN.

Automatic Pipe bending machine/Metal Sheet press Brake 100T/3200

1. Servo control technology supported

2. Digital display

3. 1 year warranty

4. packaging detaile: with plastic bag or according to the customers' requirements.

Standard Equipments

Control System: DELEM DA52S

Hydraulics System: Germany BOSCH/ Hoerbiger.

Servo drive and motor: China ESTUN.

Ball screw and linear guide: Taiwan HIWIN.

Straight-line guide: Taiwan HIWIN.

Main electrical elements:TE/OMROM/SIEMENS.

Connector:Germany EMB

Seal ring: Germany FIETZ or Japanese VALQUA

Raster Ruler: Heidemhain Germany

Standard axes:Y1,Y2,X and V( V for crowning table)

Optional

Front Support

Double Linear Guide

Laser Guards

Light Guards

Multi-axes Back gauge mechanism

Features

Overall welded and processed structure.

Closed loop control mode composed of electric-hydraulic servo valve and measure ruler.

Ensure the highest control precision, bending accuracy and repositioning accuracy are also reach to the highest level.

Back gauge mechanism can be multi-axes controlled.

Integrated hydraulic system decreases the pipe connections, oil leakage, and increases the stability and overall beautifies.

Worktable equipped with hydraulic and mechanical compensation to avoid the deformed upper beam from affecting the quality of the work piece, it is adjusted automatically by the CNC controller with convenient and accuracy.

CNC controller normally uses Holland DELEM, Italy ESA, Swiss CYBELEC, all with multi-languages.

Our worshop:

IF YOU NEED TO KNOW US MORE,

VIA: www.zymt.com.cn

Packaging & Shipping

(1)Before packing, the machine tool will be testing for 48 hours to ensure all the equipment is 100% qualitied.

(2)Before loading, stable package, professional and skilled loader reduce damage of product during transport.

(3)After loading, our professional documentary staff will follow the order till the product departs from port.

Our Services

1. Shearing blades and accessories-Customized to your specifications.In our shearing blades, our focus is on first-class, practical, well-thought-out upper and lower tools. Our tools offer solutions to your application cases-even for complex technical ones.

2. Service package

Basic: we offer you rapid trouble shooting through telephone support and costs for on-site missions are reduced.

Special: Engineers available to service machinery overseas for the necessary maintenance.

Partner: Our located dealers or customers who sell or use our machines are fully behind you, they are our friendly partner and supply good advice to you.

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

You May Like:

Product (999)

- shearing machine (421)

- press brake (559)

- Others (19)

.jpg)

.jpg)